For more than a century, we’ve led the way in custom metal fabrication for the country’s key industries.

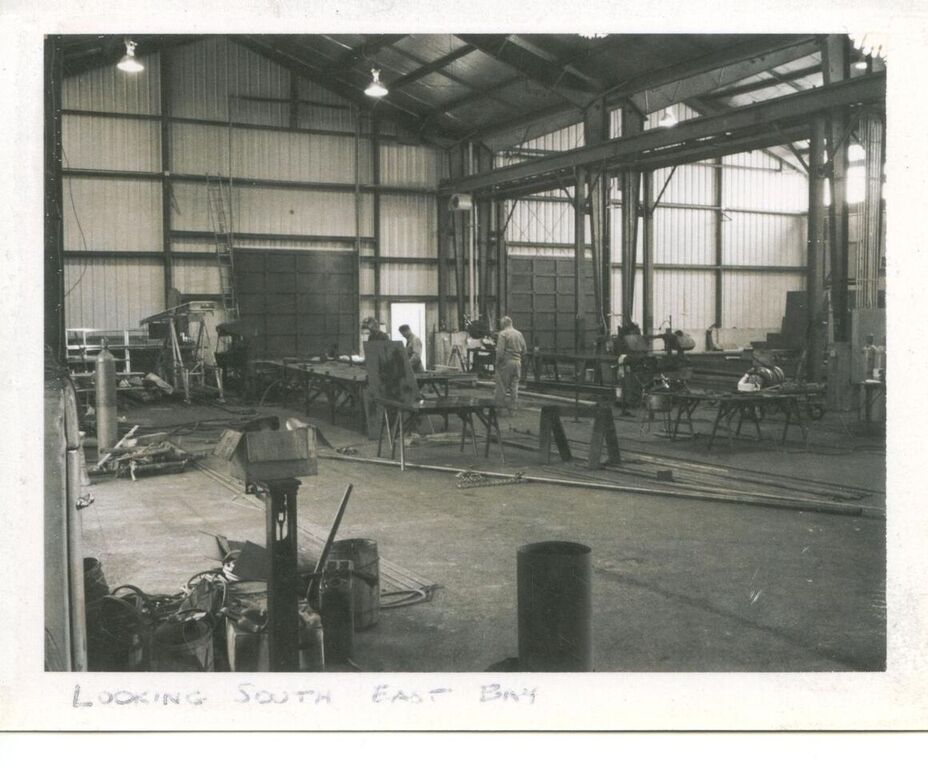

Satisfying our customers through innovative engineering, skilled welding and excellent customer service has always been our highest priority. With more than 80,000 square feet of production space and 100 skilled employees, we’re able to meet your largest and most complex metal fabrication needs.

Our history

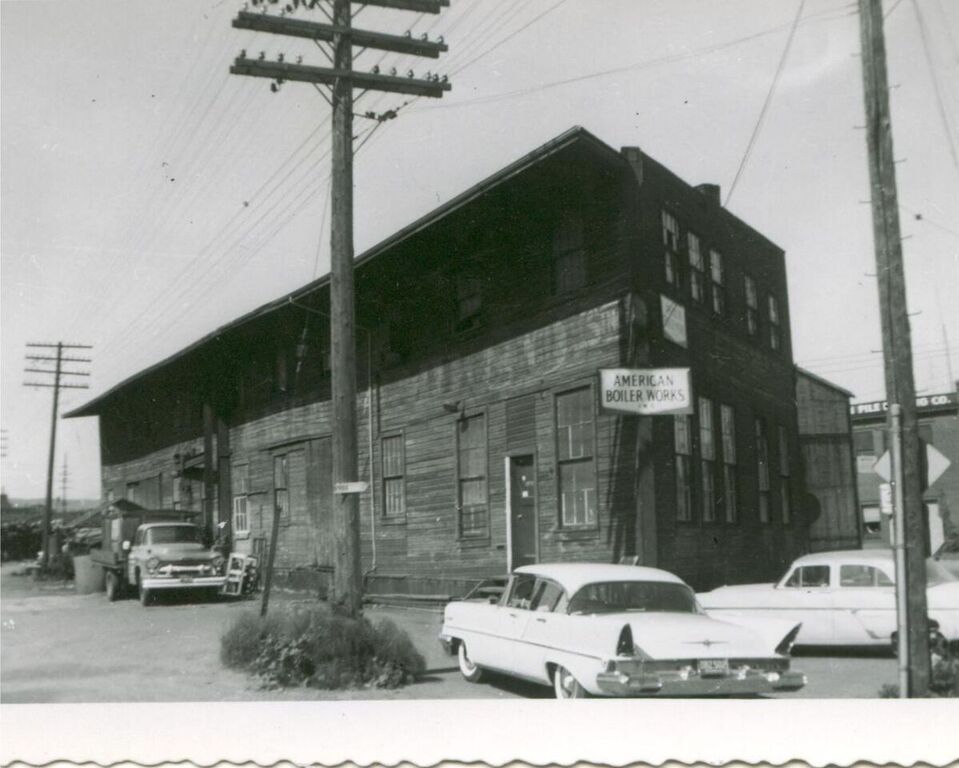

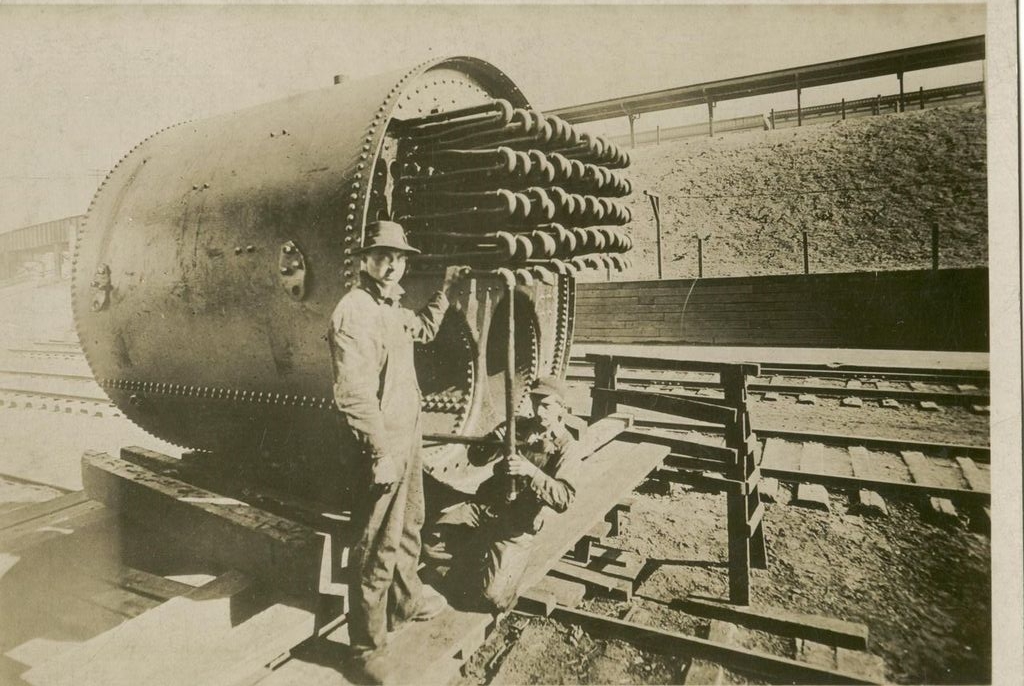

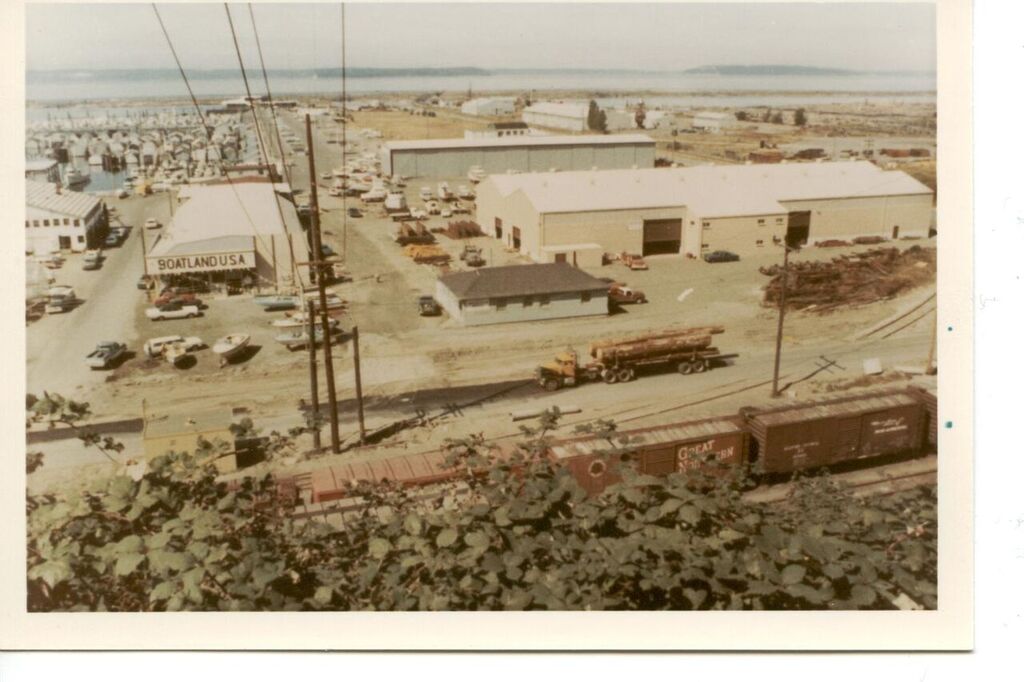

Our story begins in the 1890s when Eric W. Molander founded Key City Boiler Works—a boiler-making business for the maritime and logging industries—in the seaside town of Port Townsend, WA. In 1908, Molander relocated the business to Everett, WA and changed the name to American Boiler and Iron Works, later shortened to American Boiler Works. It was the first boiler manufacturing plant in the Pacific Northwest.

In the decades that followed, we move to Arlington, WA, expanded our capabilities and diversified into the aerospace, defense, energy and nuclear markets. In 2001, we changed our name to ABW Technologies, Inc. to better represent our broad range of services and focus on innovation.

“Our customers’ needs have evolved beyond the traditional fabrication projects we were founded on over a century ago. Their businesses are more sophisticated than ever before, and we’re continually investing in innovative equipment and experienced personnel to ensure their success.”