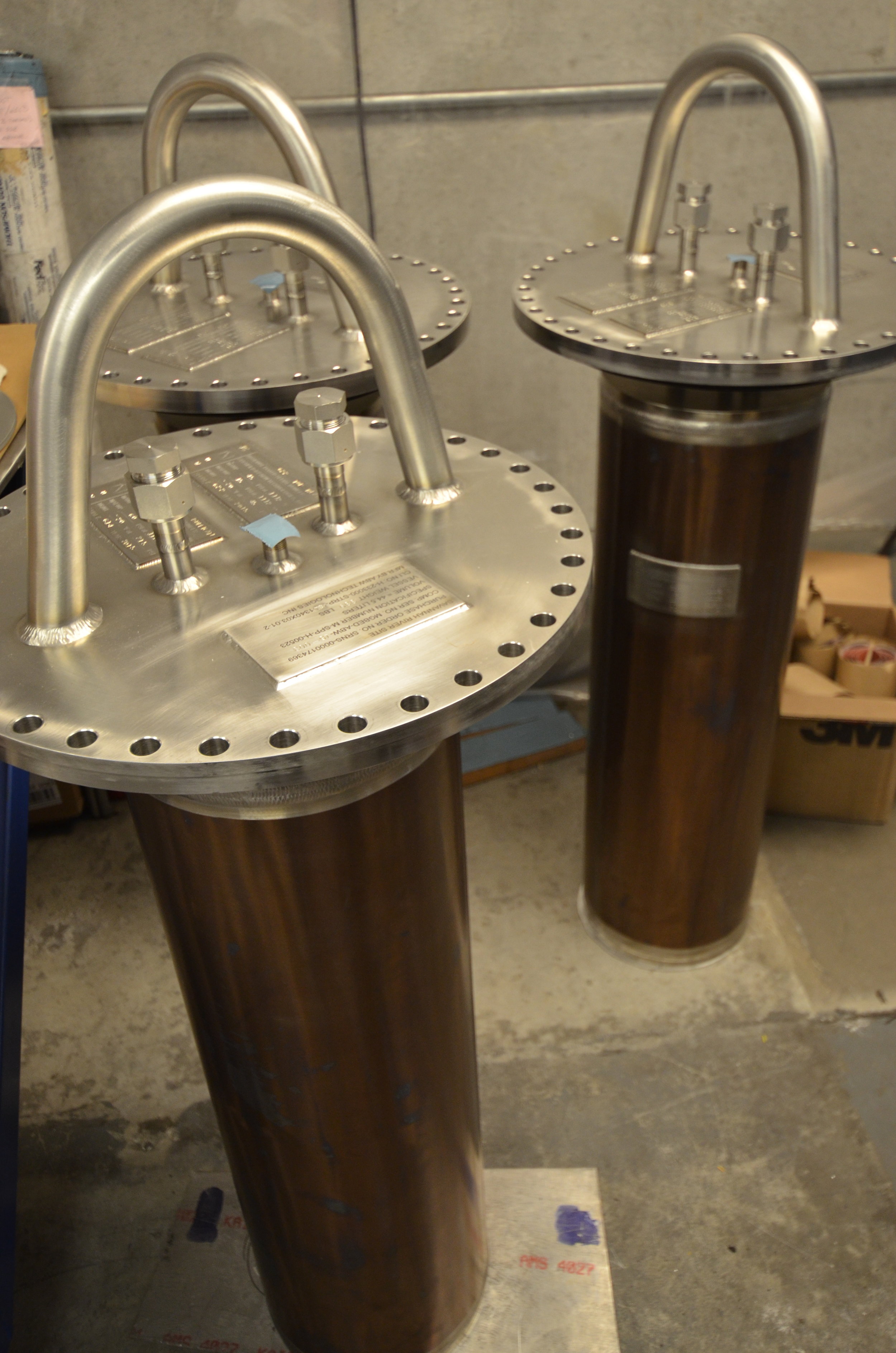

We registered our first pressure vessel back in 1949 and they've been a bedrock of our services ever since.

Over the years we've produced a wide variety and sizes of tanks and vessels, from temperature-regulating jacketed vessels to vacuum chambers spanning 12' in diameter and 40' in length. With ASME U, U2 and R stamps, we ensure our vessels and tanks are produced to the highest possible standards.

Our facilities in Arlington, WA include a 70-ton bridge crane, state-of-the-art paint and blast booths, and one of the largest rolling machines in the region. We have the skills, equipment and experience required to produce large-scale, highly customized tanks and vessels for a range of purposes and industries.

Tank and vessel types

We're able to design and fabricate a vast range of tanks and vessels, varying greatly in size, purpose and complexity. Each project is overseen by a team of expert welders, project managers and quality control inspectors to guarantee excellent quality.

We routinely produce:

- Vertical tanks

- Horizontal tanks

- Vacuum chambers

- Jacketed vessels

- Heat exchangers

- Drain tanks

- Storage casks

- Special process tanks and vessels, including decanters and mag beds.

Industries

We've produced tanks and vessels for many different industries and are able to adapt our work to the specific requirements and regulations of each.

Industries we serve include:

- Energy

- Aerospace

- Defense

- Nuclear

- Pulp / paper mills

Quality assurance and certifications

Project Gallery

Testing and inspection

Our on-site team includes:

- AWS QC1 Certified Weld Inspectors

- Mechanical and receiving inspectors

- SNT-TC-1A Ultrasonic Level II inspectors

- SNT-TC-1A Visual Inspection Level II inspectors

- SNT-TC-1A Liquid Penetrant Level II inspectors

- SNT-TC-1A Magnetic Particle Level II inspectors

- SNT-TC-1A Leak Testing Level II and III inspectors

Quality assurance programs

- ASME Section IX

- NQA-1

- AS 9100:2014

- ISO 9001:2008

- AISC BU, SPE-P1

ASME and National Board

ASME U & U2 - authorization by the American Society of Mechanical Engineers to manufacture boilers and pressure vessels.

"NB" - certificate of authorization from the National Board of Boiler & Pressure Vessel Inspectors to register boilers and pressure vessels.

"R" - certificate of authorization from the National Board of Boiler & Pressure Vessel Inspectors to repair and/or alter boilers, pressure vessels and other pressure-retaining items.

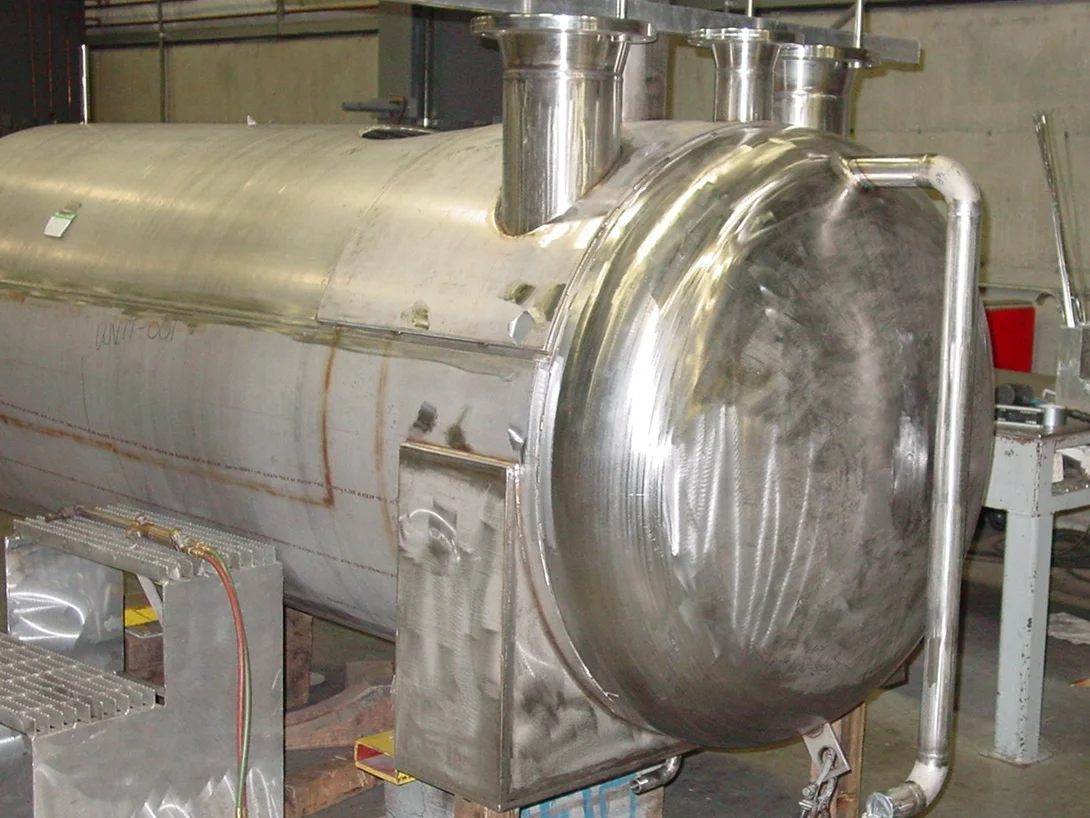

Corroded pressure vessel in for repairs at ABW.

Tank and vessel repairs

In some cases, it's faster and more cost-efficient to repair damaged or aging tanks and vessels, rather than replacing them entirely.

Our "R" stamp qualifies us to repair tanks and vessels that are faulty due to corrosion, poor design or workmanship, or general wear and tear. We're also able to modify existing vessels for new purposes.

All of our repairs and alterations are in accordance with ASME code.